I. Specification

|

model |

SF-J930 |

SF-J1080 |

|

Cutting method |

Platform |

platform |

|

Max. Paper size mm |

930×550 |

1080×780 |

|

Max.roller diameter mm |

1600 |

1600 |

|

Max.cutting size mm |

880×510 |

1010×680 |

|

Paper gram weight g/㎡ |

130-450 |

130-450 |

|

Max.cutting speed mm |

6000-8000 |

6000-8000 |

|

Max.pile height mm |

950 |

1000 |

|

Max.pressure N/cm² |

250 |

300 |

|

Cutting precision mm |

±0.2 |

±0.2 |

|

Total power kw |

16.5 |

20 |

|

dimension mm |

5200×1700×2100 |

6200×2200×2200 |

I. Introduction

SF-J series automatic web die-cutting machine based on solid technology, adopt international advanced technology, has a high stability, high safety performance, high precision of the finished product. The main electric components, spare parts, standard parts are all adopts famous brands, especially the cutting heart is following the structure of BOBST, worm gear provide high cutting pressure. Servo motor control paper feeding, color marks testing and tracing, achieve creasing, cutting and collecting functions. The machine is suitable for matching with the web printing equipment and can process many kinds of carton boxes.

This machine using computer control system to achieve whole machine automation, through man-machine interface to display working status and faults position. Many sensors and security devices ensuring operator’s safety and machine working.

II. Main structure

III.

a) feeding unit

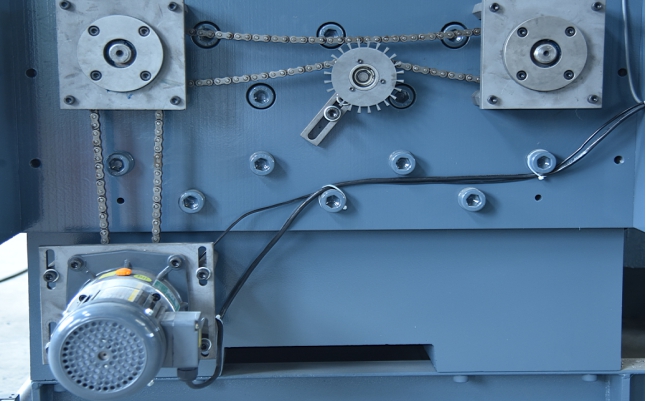

Adopts chain type pneumatic roller unwind, tension control unwind speed.

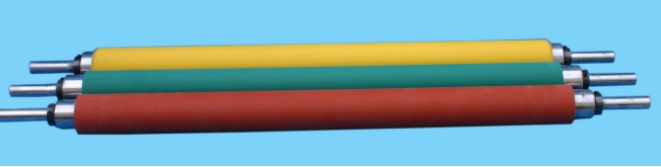

b) Rubber roller

High quality rubber roller, wear-resisting and friction performance excellently.

3、Web Guide Unit

Adopts micro motion motor provide driving power, the operator can control the paper left or right offsetting when the machine at automatic type by manual.

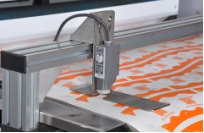

4、Die cutting unit

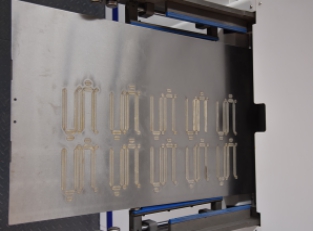

Die cutting case: pneumatic lock cutting plate to avoid come off from the machine.

Die cutting plate: 65Mn steel plate heating treatment, high hardness and flatness.

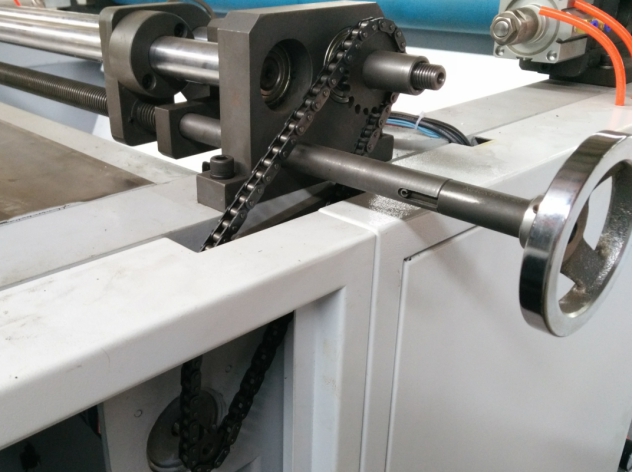

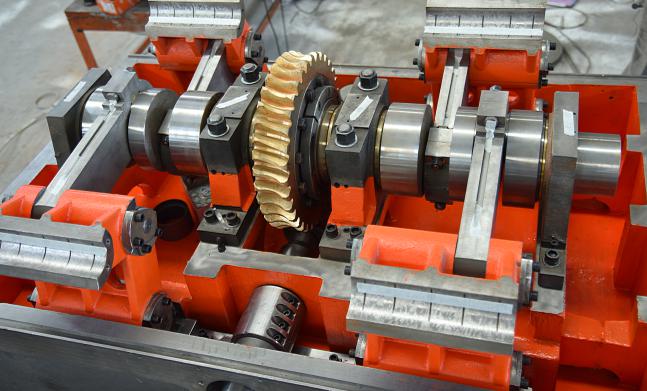

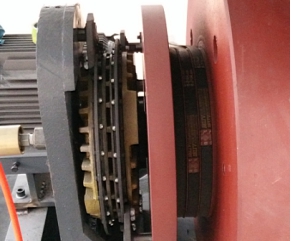

Driving device: perfect driving design makes the cutting accurately while machine running in high speed, main drive adopts worm gear and special designed bent axle rod device, high hardness and wear resistant bronze bearing bush reduce movement error, has features of low noise, smooth running and high cutting pressure.

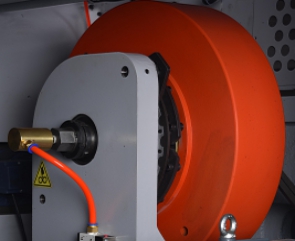

Pneumatic clutch brake: through adjust the air pressure to control the driving torque, low noise and high brake performance. The machine will shut down automatically if overload happened, response sensitive and fast.

Electrical control pressure: accurate and fast to achieve die-cutting pressure adjustment.

5. Delivery unit

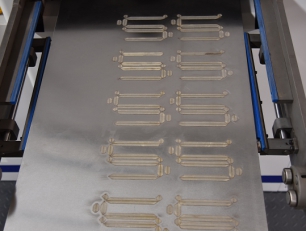

The cut paper will be separated and collected by separation system. The non-stop delivery system can achieve replace the finished paper while machine working. When the delivery paper pile is full, the machine will alarm to inform operator collect the paper.

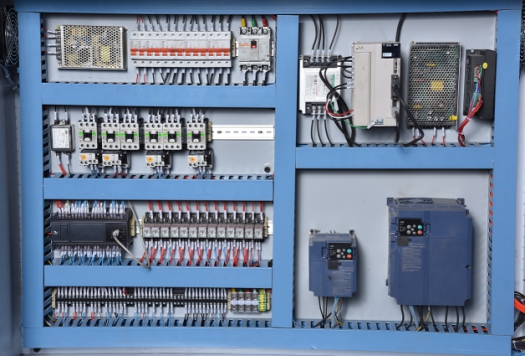

6. Electrical cabinet

Motor: famous brand of frequency converter control the main motor, with features of low energy and high efficiency. Machine main motor and main feeding motor are adopts fam, , , ous brand, long lifespan and low , noise.

PLC and man-machine interface: screen display the machine running data and status, all of the parameter can be set through the screen.

Electrical control system: adopts micro computer control, encoder angle detect and control, photoelectric chase and detect, achieving from paper feeding, convey, die-cutting and delivering process automatic control and detect.

Security devices: machine alarming when failure happens, and automatic shut down for protection.

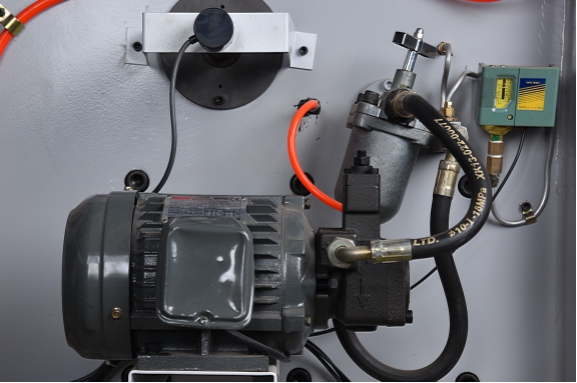

7. Lubrication unit

Adopts forced lubrication system to ensure main driving oil supply regularly, machine will shut down for protection if oil pressure is low.

Main configuration

© شرکت بازرگانی تانگشن جیاسون (با مسئولیت محدود) Tel/Fax:+86-315-6110308 / +86-13623253438 E-mail:sales@jiasun.com.cn