eatures:

●BKJ1307/1310/1410 is specialized in the production of high-precision automatic cardboard lamination for thin paper, cardboard, gray cardboard, art paper, etc. to meet the demands of printed cardboard lamination. It is with the features of high precision, non-deformation and flatness.

●The main parts of the machine come from well-known brand either from abroad or domestic with long service life and good stability. Electrical components use international famous brands to ensure the reliability.

●The machine is equipped with five sucking and four forwarding feeder, differential speed registration system, synchronization lamination and other innovative design. It is made according to the European CE standards. The machine can also do automatic monitoring, automatic detection, fault display and alarming from feeding, registration, lamination to delivery.

I. Specifications

|

Model |

1307 |

1310 |

1410 |

|

Max. Sheet Size (WxL) |

1270mmx720mm |

1270mmx1000mm |

1410mmx1100mm |

|

Min. Sheet Size (WxL) |

500mmx380mm |

500mmx400mm |

500mmx400mm |

|

Thickness of Upper Paper |

100~800g/㎡ |

100~800g/㎡ |

100~800g/㎡ |

|

Thickness of Bottom Paper |

200~2000g/㎡ |

200~2000g/㎡ |

200~2000g/㎡ |

|

Max. Speed |

150pcs/min |

120pcs/min |

120pcs/min |

|

Lamination Precision |

±0.5mmmm② |

±0.5mmmm② |

±0.5mmmm② |

|

Total Weight |

9000kg |

9000kg |

11000kg |

|

Total Length |

10500 |

10500 |

12000 |

|

Operation Space |

3000x13500 |

3000x13500 |

3000x13500 |

|

Power |

3~380V(50Hz) |

3~380V(50Hz) |

3~380V(50Hz) |

depends on the quality of paper ②Standard hard cardboard

II. Main features of the machine

a) High precision: ±0.5mm which can make the latter process more easy to achieve.

b) High speed: 150 pieces per minutes

c) Wide range of application: 100-800g face paper and 200-2000g bottom paper can be used on the machine.

d) Glue saving: it can save 5g/m2 with the unique anilox roller

III. Introduction of The Machine:

a) Function of the machine:

The machine can laminate card to card together to make tags, boxes etc.

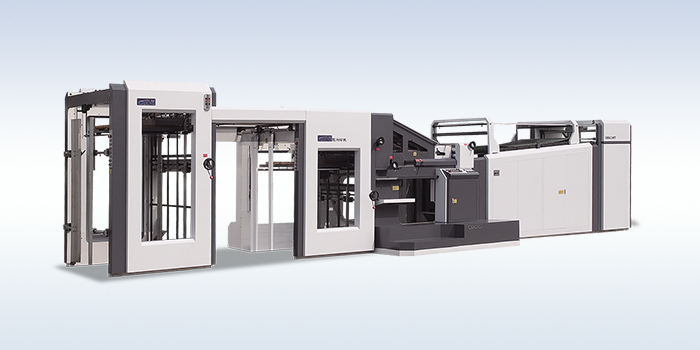

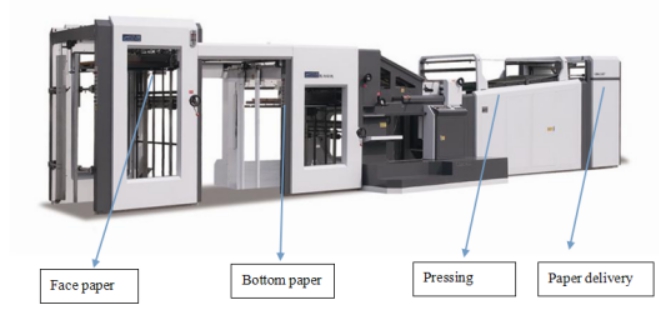

b) Structure:

Upper Feeder: 100-800 gsm paper

Lower Feeder: 200-2000 gsm paper

Compressor: Compress the laminated paper and conveying them to the piling part.

Paper piling part: To pile the laminated paper

Gluing Part: To glue on the bottom paper

Registration Part: To ensure precise paper lamination.

IV. Features By Part;

a) Feeding part

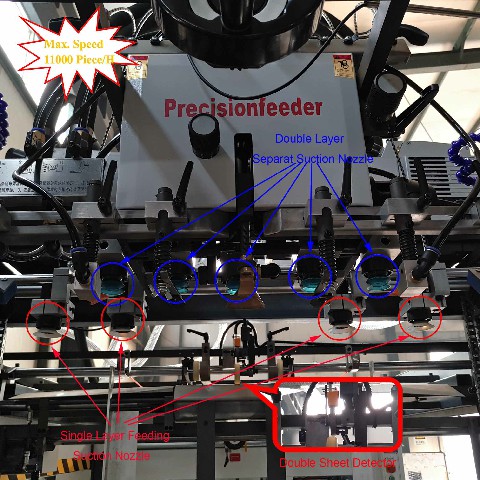

The machine adopts mature high speed feeding structure with simple operation, easy

maintenance which can fit to various kinds of paper.

i. Four sucking and five forwarding which can do feeding of thin paper and wrapped paper.

ii. Double sucking rubber and single rubber forwarding which can avoid effectively double paper.

iii. Equipped with two blower to ensure paper separation smoothly.

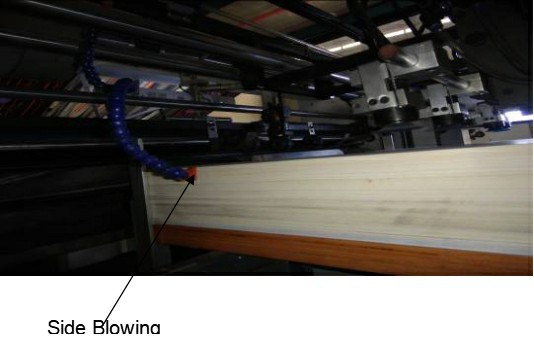

b) Side blower

There are two side blowers as well. The position of the side blower can be adjusted to ensure the smooth feeding of paper.

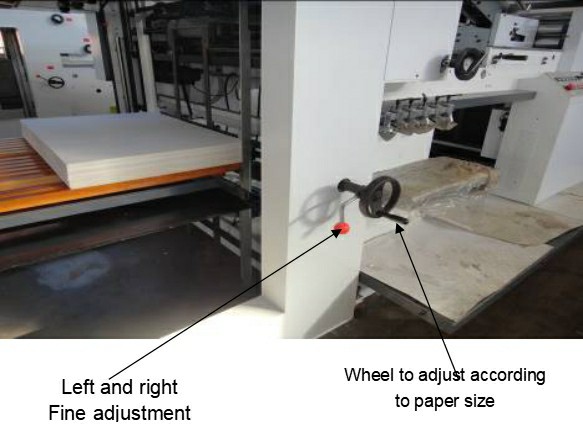

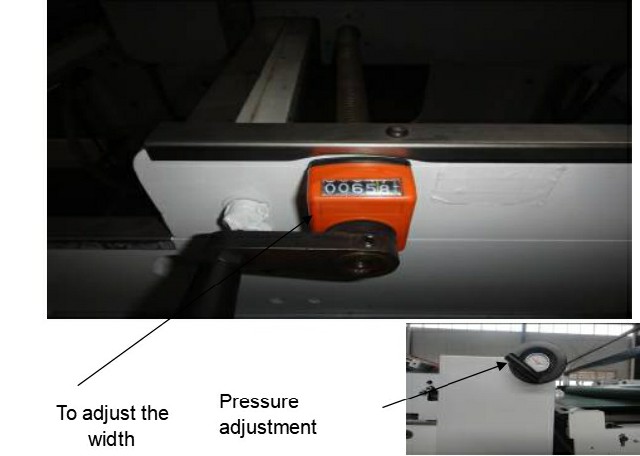

c) Registration Adjustment:

i. The operator can adjust the registration place of the paper either through the wheel or the fine adjustment handle to adjust the left and right position.

ii. For the in lamination, you can adjust the wheel according to the number it shows.

iii. The registration of lamination can be done when the paper is running. When fine adjustment is needed, you can only press related button to do the adjustment.

viii. Paper Jam detector is equipped after lamination.

© Tangshan Jiasun Import & Export Co.,Ltd 冀ICP备17034427号-1 Tel:+86-315-6110308 / +86-13623253438 E-mail:sales@jiasun.com.cn