I. Main features

◆Aligning precision can reach 0-1.5mm(3 ply) and 0-2mm (5ply).

◆Machine adopts ceramic heating bar and covered with stainless steel tube, with features of fast heating and long service life.

◆Servo motor and motion control system control the sheet side positioning and registration.

II. Machine specification

|

Model |

MTAB-C1800 |

MTAB-C2300 |

|

Box width * box height ( paper moving direction) | ||

|

Max. Sheet Size |

950*1000mm |

1200*1000mm |

|

Min. Sheet Size |

350*310mm |

350*310mm |

|

Sheet Thickness |

Corrugated board E, B, C, A, BC | |

|

Total Power |

16KW |

16KW |

|

Max. Speed |

3000pcs/h |

3000pcs/h |

|

Weight |

1.8T |

2T |

|

Dimension (main machine) |

2240*2580*1360mm |

2240*3080*1360mm |

|

Power Supply |

3 phase 380V 50Hz |

3 phase 380V 50Hz |

III. Main parts introduction

a) Feeding unit

|

|

|

u Independent control with double suction and double delivery to ensure smooth and reliable paper feeding and higher paper feeding accuracy.

u The servo motor and belts feeding method ensures the smooth and accurate paper feeding. The belt adjustment adopts linear bearing design, which makes sliding easy and convenient.

b) Gluing unit

|

|

|

u It adopts hot and cold double-gluing structure. The hot glue adopts aluminum glue box to heat up quickly, and the cold glue uses stainless steel glue box to resist corrosion.

c) Aligning unit

|

|

|

u The AB pieces sheets positioning and gluing action adopts our servo motor and motion control system , it can ensure the accurate sheet positioning and make the digital adjustment more convenient.

u The servo aligning action is controllable, only need the operator input the data and the servo will adjust automatically.

u Four unique independent front-lay technology with features of easy to be adjusted, non-adhesive and faster positioning.

u Adjustable front lay from 0 to 40mm, which can do special shaped products.

d) Human-machine interface

|

|

|

u The control panel has touch screen to display the machine working speed, production yield and fault.

u Easy operation and suit for human engineering habits, the operator can do operation when machine working to reduce the order change time.

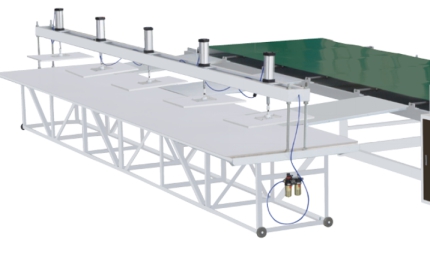

e) Conveyor unit

u The station type structure can increase the working efficiency effectively.

u Equip with five pneumatic pressing stations, we can add more station if necessary.

f) Electric components

u Delta system combine with advanced motion control system can ensure the machine working stably and reliably.

u Famous brand of parts to ensure the long service life.

IV. Configuration

|

Name |

Brand |

|

Button |

Tiande |

|

contactor |

Schneider |

|

Frequency converter |

Delta |

|

PLC |

Delta |

|

Touch screen |

Delta |

|

photoelectric |

Delta |

|

Servo Motor |

MIGE |

|

Power Supply |

Meanwell |

© Tangshan Jiasun Import & Export Co.,Ltd 冀ICP备17034427号-1 Tel:+86-315-6110308 / +86-13623253438 E-mail:sales@jiasun.com.cn