I.Price:

| NAME | MODEL | UNIT | UNIT PRICE |

| Automatic Die-Cutting and Creasing Machine with Stripping | Excellent 800TS | 1 SET |

II.Specifications

| Model | 880TS |

| Max. Sheet Size (WxL) | 810 x 650mm |

| Min. Sheet Size (WxL) | 370 x 250mm |

| Max Die Cutting Size | 800 x 640mm |

| Paper Thickness | Cardboard 0.1-2.0mm |

| Cardboard 80g/㎡-2000g/㎡ | |

| Corrugated Board≤4mm | |

| Paper feeding height | 1350mm(with wooden Pallet) |

| Paper delivering height | 1200mm(with wooden Pallet) |

| Die cutting precise | ≤±0.075mm |

| Max Speed | 8500s/h |

| Dimension(length*wide*height) | 7311 x 3782 x 2302mm |

| Total Weight | About 15000KG |

| Power | 15Kw |

| Main Motor Power | 11Kw |

| Pressure | 300T |

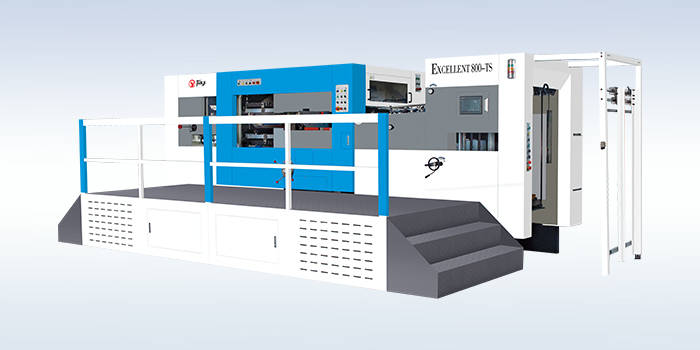

III.Machine Profile:

IV.Standard Configuration And Function

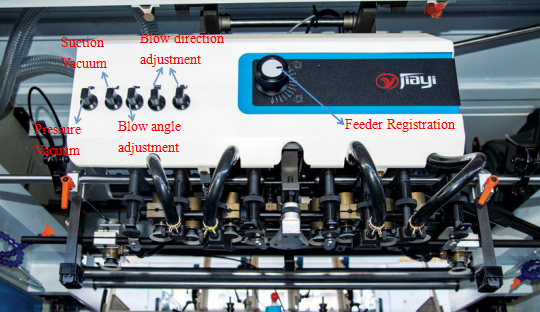

a) High Speed Feeder & Paper Feeding Department:

● Fish scale feeding method, max. speed can reach 125 sheets/min

●Feeder with correction function, with two-sided eight-speed calibration correction adjustment, the requirements of paper loading is also greatly reduced.

●4 sucking suckers and 6 delivery sucker, the suction head can adjust angle and height according to the paper deformation condition. Stable feeding, applicable 80g-2000g cardboard and ≤4mm corrugated.

● 3 anti-collision safety designs,multi-directional protection feeder head

● Non-stop high-speed feeder, equipped with mechanical dual gear dual sheet detection mechanism

● Both the operating surface and the transmission surface are equipped with one push-pull dual-purpose side lay devices,push and pull can be easily converted

● The main paper feed motor is controlled by frequency converter to realize the function of fast down and slow up

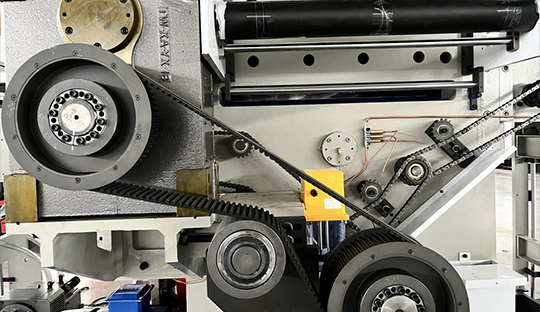

2) Die Cutting Unit:

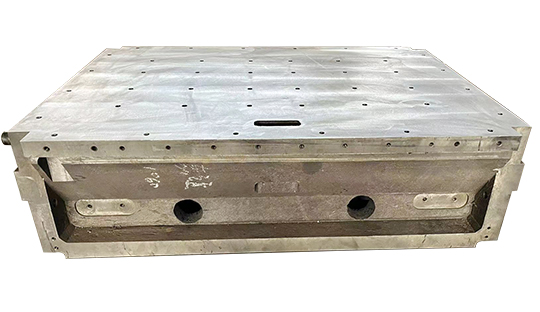

●The bottom, moving, upper platform, the both transmission and operating surfaces are cast iron wall panels

●The flatness of the moving and the upper platform is less than 0.01mm(≤1㎡).

● Equipped with a centrally positioned quick-locking die-cutting frame, the plate change time is increased by more than 30%

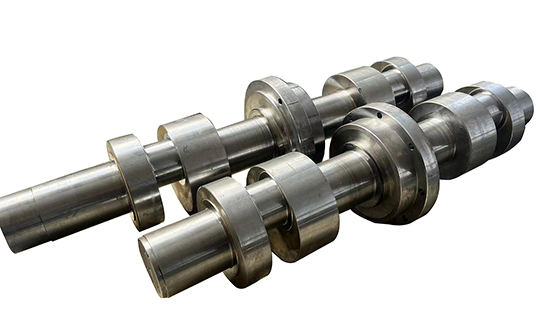

● 40 Cr crankshaft

● The worm gears and worms adopts German SEW which have a large number of contact teeth and are not easy to wear.

● The max. die cutting pressure can be achieve 300T.

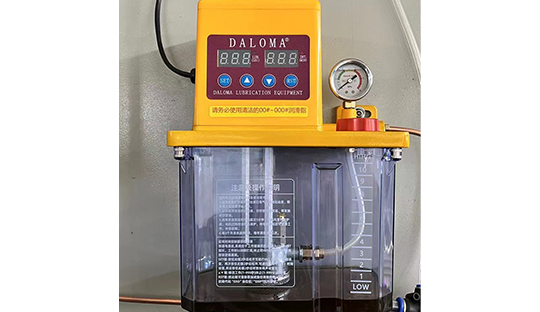

● Lubricating oil secondary filtration system in main transmission box

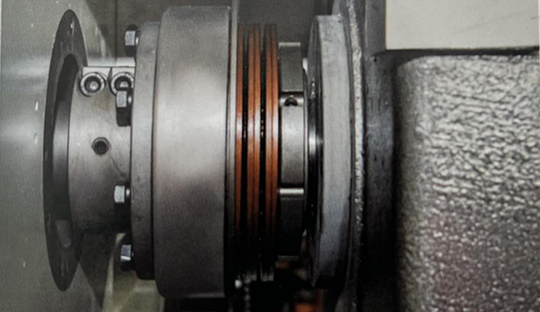

● Machine with imported Torsion limited overload protector

● Five sets of imported anodized aluminum alloy gripper bar and positioning parts.

● The main drive is timing belt, which has the characteristics of high transmission precision and low noise

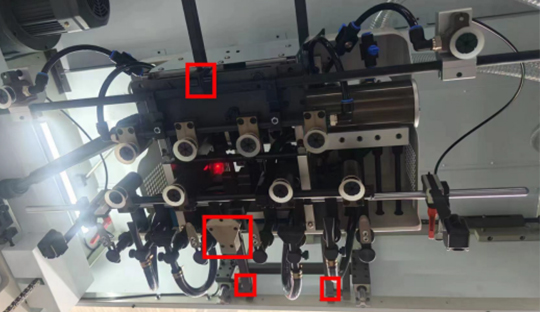

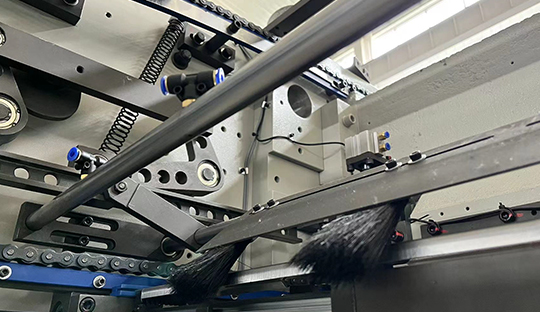

c) Stripping Unit:

The striping part of the EXCELLENT 800TS die-cutting and striping machine adopts a variety of new designs. The upper and lower striping frames adopt a centrally positioned structure, which is easy to operate and fine-adjust. The striping concave template adopts a quick locking mechanism, which is easy to operate. During repeated installation, it can be operated at the window on the operating side.

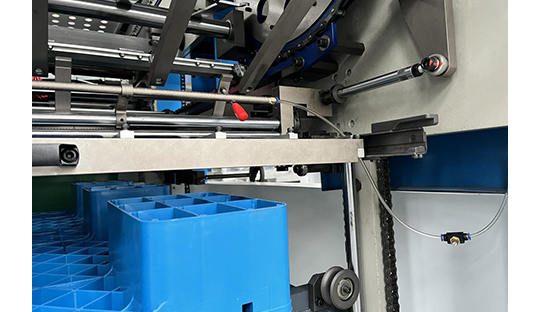

d)Delivery Unit:

● Electric secondary receiving device

● Thin paper blowing flat device,with the receiving brush, make 80 grams of cardboard easily

● Pneumatic viewing sampling mechanism

●With paper insertion counting function

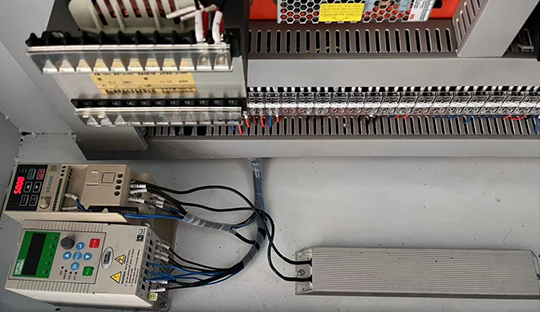

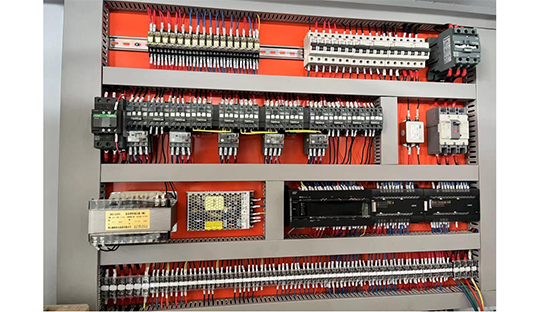

e) Electricity:

The EXCELLENT 1060TS automatic die-cutting and creasing machine with stripping has passed the EU CE safety certification.

● The safety door circuit and emergency stop circuit are all controlled by safety relay ducal circuits Which can ensure the worker safety.

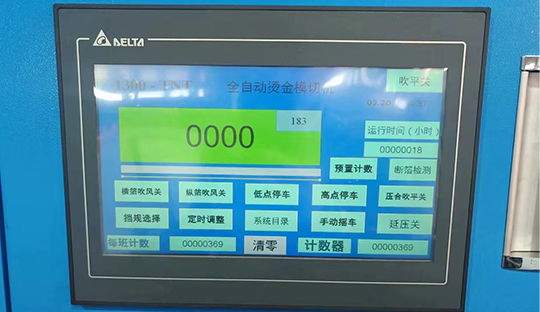

● The combination of PLC and human-machine interface HMI makes it more convenient for operators to “communicate” with machines

v.Other information:

© Tangshan Jiasun Import & Export Co.,Ltd 冀ICP备17034427号-1 Tel:+86-315-6110308 / +86-13623253438 E-mail:sales@jiasun.com.cn