I.Price:

| NAME | MODEL | UNIT | UNIT PRICE |

| Automatic Die-Cutting and Foil Stamping Machine | Excellent 1500TN | 1 SET |

II.Specifications

| Model | 1500TN |

| Max. Sheet Size (WxL) | 1500 x 1100mm |

| Min. Sheet Size (WxL) | 400 x 370mm |

| Max Die Cutting Size | 1480 x 1080mm |

| Paper Thickness | Cardboard 0.1-2.0mm |

| Cardboard 80g/㎡-2000g/㎡ | |

| Corrugated Board≤4mm | |

| Paper feeding height | 1700mm(with wooden Pallet) |

| Paper delivering height | 1350mm(with wooden Pallet) |

| Die cutting precise | ≤±0.10mm |

| Gripper Margin | 7-17mm |

| Max Speed | 5000s/h |

| Dimension(length*wide*height) | 10244x 2727(no pedal plate) x 2815mm |

| Total Weight | About 28000KG |

| Power | 20Kw |

| Main Motor Power | 15Kw |

| Pressure | 500T |

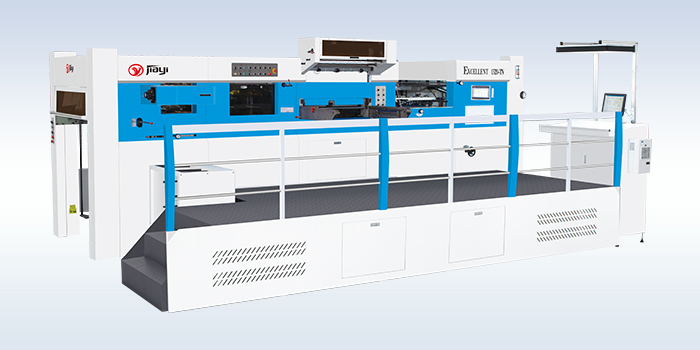

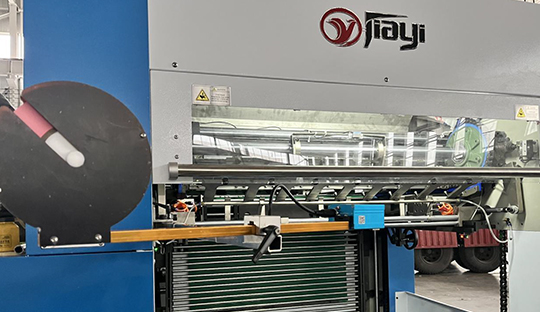

III.Machine Profile:

IV.Standard Configuration And Function

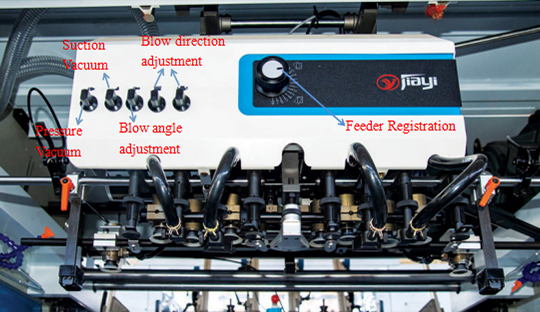

a) a)High Speed Feeder & Paper Feeding Department:

● Fish scale feeding method, max. speed can reach 125 sheets/min

● Feeder with correction function, with two-sided eight-speed calibration correction adjustment, the requirements of paper loading is also greatly reduced.

● 4 sucking suckers and 6 delivery sucker, the suction head can adjust angle and height according to the paper deformation condition,stable feeding.

● 3 anti-collision safety designs,multi-directional protection feeder head

● Non-stop high-speed feeder, equipped with mechanical dual gear dual sheet detection mechanism

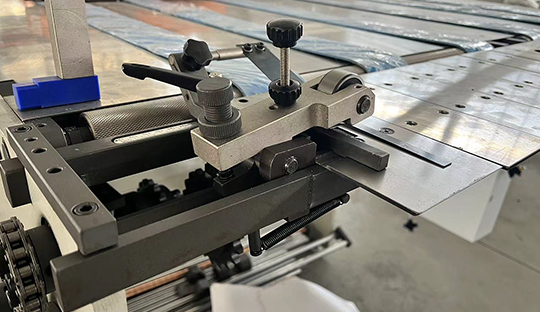

● Both the operating surface and the transmission surface are equipped with one push-pull dual-purpose side lay devices,push and pull can be easily converted

b) Die Cutting Unit:

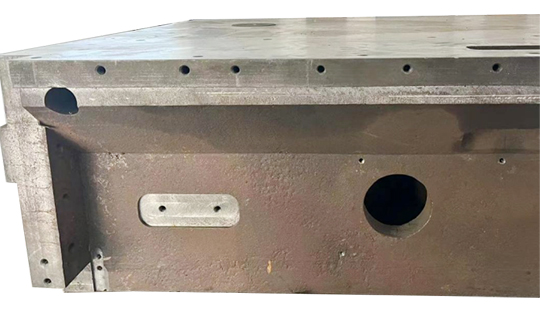

● The bottom, moving, upper platform, the both transmission and operating surfaces are cast iron wall panels

● The flatness of the moving and the upper platform is less than 0.01mm(≤1㎡).

●40 Cr crankshaft

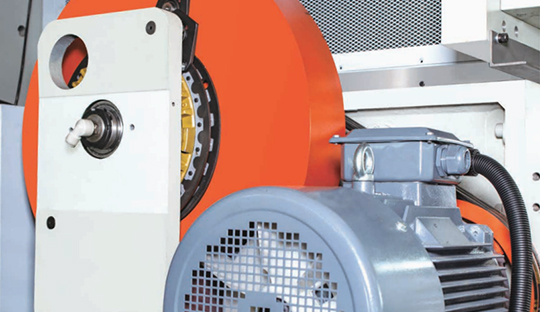

● The worm gears and worms adopts German SEW which have a large number of contact teeth and are not easy to wear.

● The max. die cutting pressure can be achieve 500T.

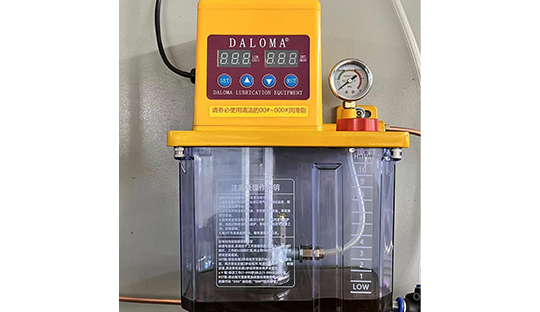

● Lubricating oil secondary filtration system in main transmission box

● Machine with imported Torsion limited overload protector

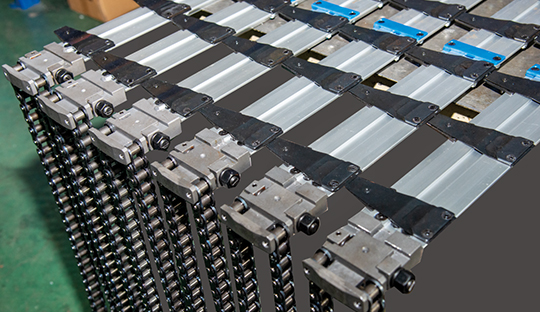

● Seven sets of imported anodized aluminum alloy gripper bar and positioning parts.

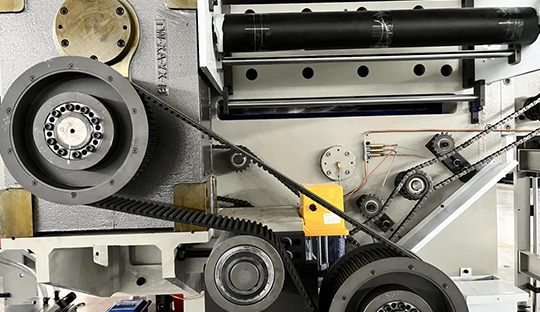

● The main drive is timing belt, which has the characteristics of high transmission precision and low noise

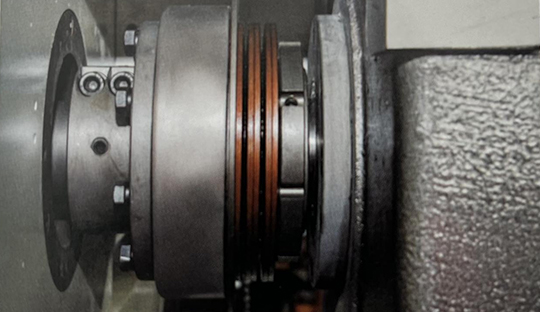

● Main transmission adopts imported pneumatic clutch brake device

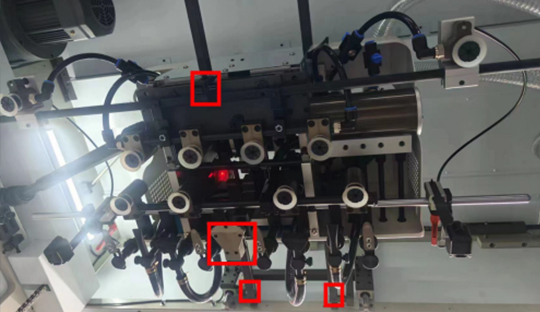

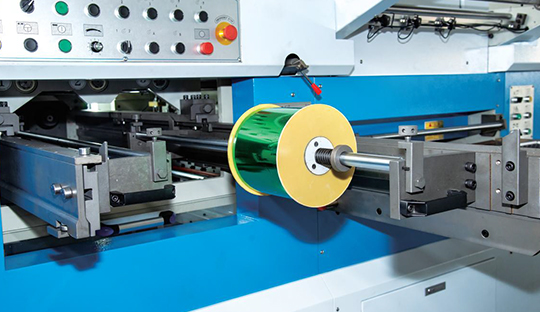

c)Foil Stamping Unit

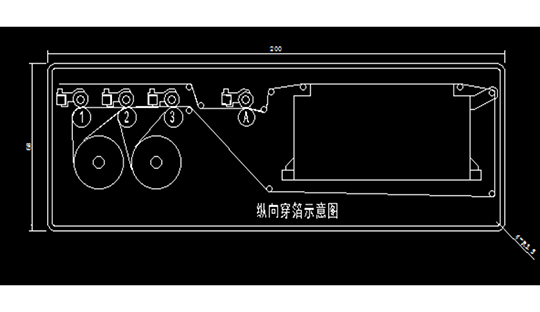

● The machine adopts 3 sets of electrochemical aluminum foil step rollers in the longitudinal direction, which are controlled by 3 AC servos respectively. It can realize step skipping and step function. At the same time, there is a synchronous foil collecting roller controlled by an AC servo to achieve synchronization of foil feeding and collecting horizontal. There are 2 anodized aluminum foil step rollers in the lateral direction, which are controlled by 2 AC servo respectively. It can also realize skip and step independently. It has advanced function and is equipped with a synchronous foil retracting roller controlled by an AC servo to achieve synchronized foil feeding and retracting.

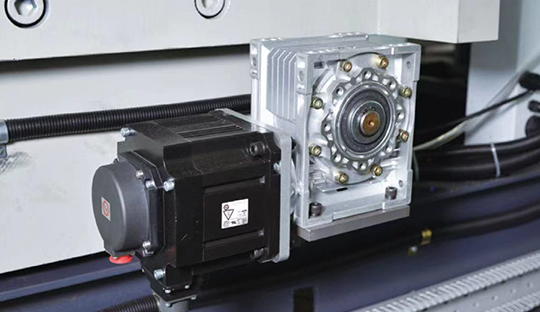

● The voltage regulating part adopts a voltage regulating mechanism controlled by a servo motor to realize automatic voltage regulating function

●The electric heating plate of this machine is divided into 24 temperature control areas, with a heating area of 1500 x 1100. It is characterized by 24 temperatures can be controlled separately, and the max heating temperature allowed in each heating area is 200°

● The machine is equipped with paper blowing and aluminum foil and paper separation devices to achieve the rapid separation of aluminum foil and paper at different times during thin paper blowing and hot stamping.

● The vertical foil rack adopts double-layer pull-out type, which can realize external replacement of foil and reduce the time and labor intensity of changing foil

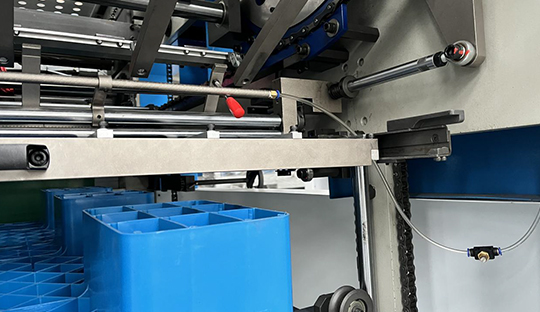

d)Delivery Unit:

● Automatic secondary paper receiving device to achieve automatic conversion between primary and secondary paper receiving

● Thin paper blowing flat device,with the receiving brush, make 80 grams of cardboard easily

Pneumatic viewing sampling mechanism

● With paper insertion counting function

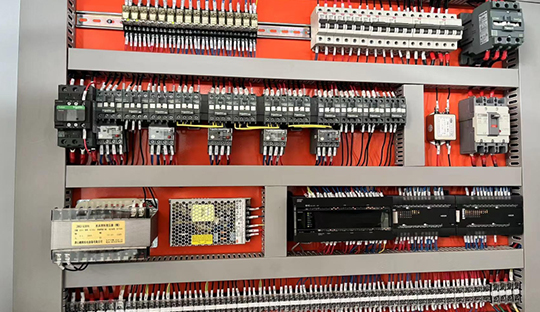

e) Electricity:

The EXCELLENT 1500TN automatic die-cutting and hot stamping machine has passed the EU CE safety certification.

● The safety door circuit and emergency stop circuit are all controlled by safety relay ducal circuits Which can ensure the worker safety.

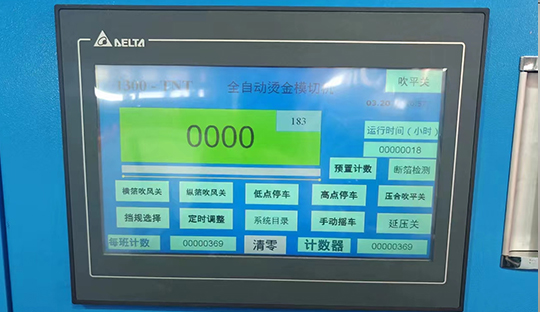

The combination of PLC and human-machine interface HMI makes it more convenient for operators to “communicate” with machines

f) Brands or origin of main electric parts applied:

v.Other information:

© Tangshan Jiasun Import & Export Co.,Ltd 冀ICP备17034427号-1 Tel:+86-315-6110308 / +86-13623253438 E-mail:sales@jiasun.com.cn